Insulate your house with thermal break windows

Energy efficiency and thermal break: how to limit heat loss with thermal break windows and other window insulation solutions.

In architecture, windows and doors play a fundamental role, allowing ventilation and natural lighting of rooms, as well as constituting a barrier to the action of atmospheric agents. Closely related to the theme of windows and doors is that of thermal insulation.

This term identifies all the technological and construction choices that are essential to reduce heat loss to the outside in winter and heat gain in summer. These solutions also directly concern the characteristics and performance of windows and doors, considered one of the main causes of heat loss.

Thermal cutting: what is it?

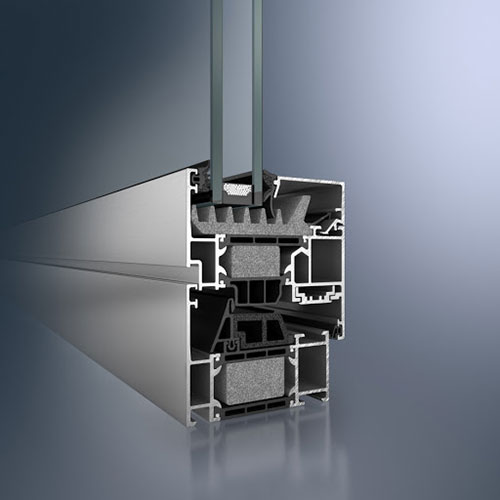

To solve this problem, thermal break is used, a system usually used for aluminium windows or for steel frames. The fixtures thermal break They "cut" the thermal bridge thanks to their structure and the insertion of plastic strips that interrupt the continuity of the metal, thus ensuring a better seal against heat loss.

Many of the traditional window frames, also known as cold cut, as well as no longer complying with energy saving regulations, also have the problem of high thermal conductivity. For this reason, thermal break windows are becoming more and more popular, as they prevent the passage of heat, thus improving window insulation. In reality, there are various aspects that must be taken into consideration in order to ensure the thermal insulation of windows and doors.

Improving the thermal insulation of windows can bring multiple benefits. First of all for the environment, as good insulation reduces energy consumption and improves living comfort in the interior.

Optimising the thermal insulation of a residence is also a long-term investment. Because by improving the energy efficiency of the house, you reduce heating and cooling costs.

In addition, thanks to the tax deductions provided for energy requalification interventions there are important tax advantages that further reduce the payback time for this type of investment.

What are the factors that contribute to the thermal insulation of windows?

The transparent envelope of a building, or rather the windows and doors of a house are one of the elements that have the greatest impact on thermal insulation.

A window frame is continuously subject to thermal exchange with the outside and the most exposed part is the glass surface. For this reason it is considered that 80% of the performance of a window is guaranteed by the characteristics of the glass while the remaining 20% is guaranteed by the frame.

#1 Glass surface: the double glazing

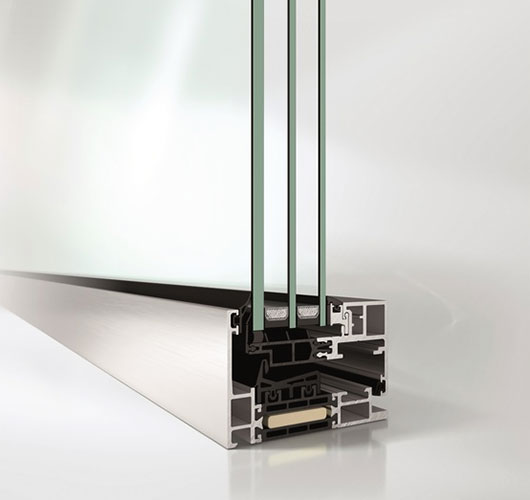

The main alternative to single glazing is double glazing. This is glass consisting of two or more panes of glass, spaced 6 to 22 mm apart.

The gap between the panes of glass plays an important role in window insulation. For specific thermal insulation requirements, the space between the panes can be increased, as can the thickness of the glass, which is usually 4 mm.

Frames with double-glazing can also be composed of three panes, in this way two chambers are created and there is greater acoustic and thermal insulation.

The insulating glass unit with gas

In order to improve the energy performance of double-glazed windows, a noble gas, such as argon and krypton, is inserted in the cavity between the two panes, which slows down the passage of heat between one pane and the other.

Glasses low-e

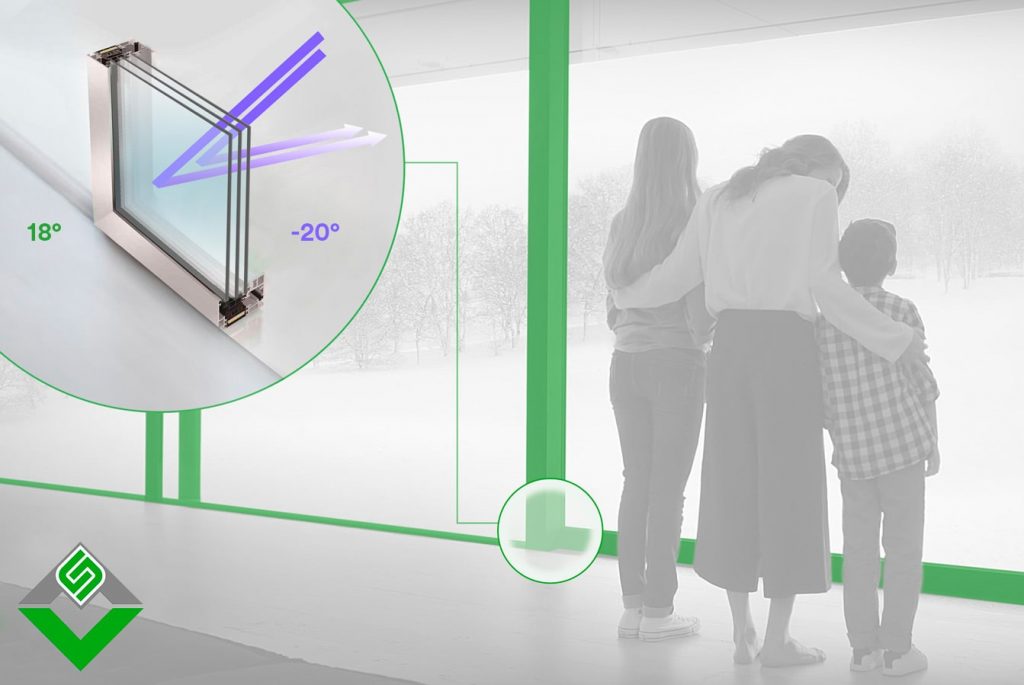

In order to meet thermal insulation requirements, an optimal solution is represented by low emission glass, designed to contain heat dispersion and retain heat. Also used on thermal break frames, low emission glass is coated with a film of metal oxides that reflect the infrared energy of long waves towards the inside of the house. Low emission glass contains heat loss by retaining heat. Therefore, in the case of double glazing, the low emission glass is placed on the inside.

Precisely because they retain heat, low emissivity glass is recommended especially in climatic zones where the winter season is particularly harsh and it is necessary to insulate against the cold and there are no particular inconveniences in the summer.

Glasses selective

Another type of glass is also used to improve the energy performance of a window frame: selective glass. These glasses, coated with particles obtained by pyrolysis, prevent heat transmission by rejecting thermal energy. A selection of the different wavelengths takes place, thus avoiding the overheating of buildings in hot periods. For this reason, unlike low-E glass, selective glass is positioned towards the outside.

The spacer channel

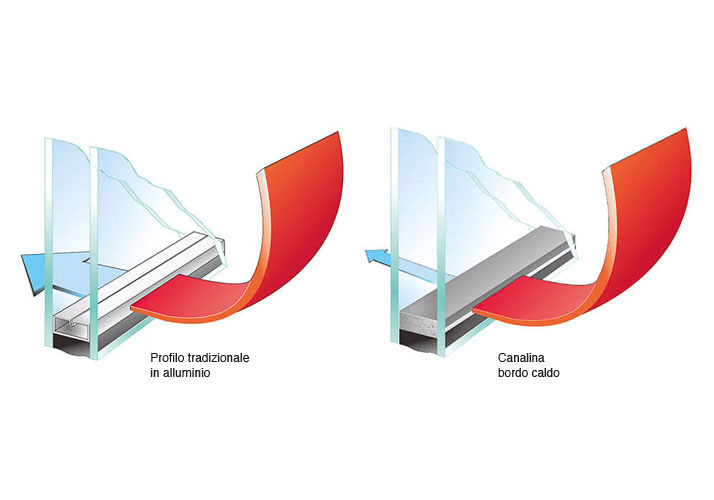

The space between the glass panes is created by the spacer gutter, a sensitive point in the window frame due to possible thermal bridges. Especially if, as in the past, they were aluminium spacer bars, which have now been replaced by "warm edge bars". The warm edge spacers are made of insulating material and in addition to joining the glass panes they also solve the problem of glass fogging.

An example of a high-performance glazed surface

In conclusion, one of the most used and performing solutions to solve the problem of thermal insulation is a glazed surface composed of three glass panes with a double cavity. The optimal composition foresees: 3+3 laminated selective external glass with two 3mm glass panes, intermediate groove between the glass panes of 15mm, 4mm plain glass pane, second 15mm air chamber and 3+3 low emissivity internal glass of 3mm. With both air chambers filled with argon gas, this solution offers a thermal transmittance Ug equal to 0,6.

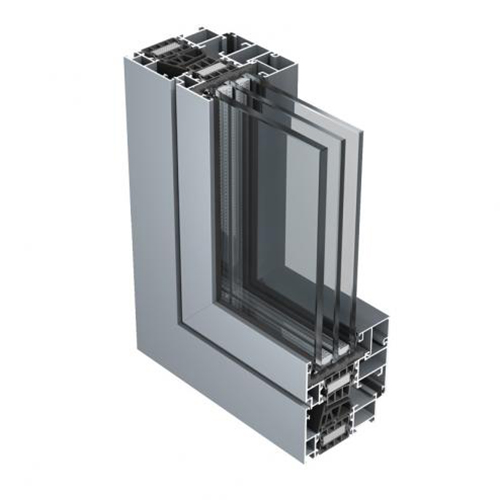

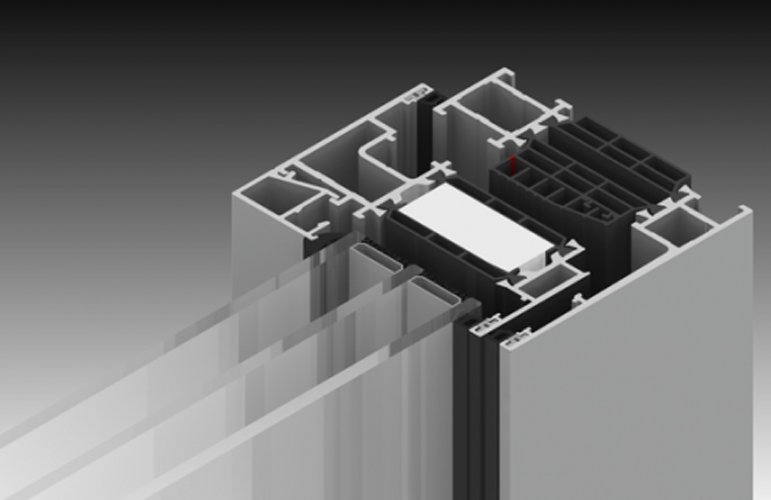

#2 The frame: thermal break frames

A window may consist of a certain number of sashes and different opening systems: casement, sliding, vasistas. These are all elements that partially determine the thermal insulation of the window frame.

But when it comes to the insulating performance of windows, what must be chosen carefully are the frame material and the characteristics of the system itself such as the number of chambers inside the profile, the type of gaskets used.

Thermal insulation: materials and frame performance

Depending on the material from which the frame is made, it contributes to a different extent to the thermal insulation performance of the windows. So, if the wooden fixtures guarantee, due to their nature, a low thermal transmittance coefficient, on the other hand there are the aluminium windowsThese are made of a material that, by its nature, is a good conductor of heat. In order to overcome this characteristic of aluminium, a thermal break is made. The aluminium frames with thermal break are made in such a way as to interrupt the continuity of the metal by blocking the thermal bridges or the passage of heat between inside and outside.

A material with low thermal conductivity is inserted into a chamber of the profile.

Like aluminium windows and doors, steel windows and doors are also made with thermal break profiles.

The characteristics of PVC window frameswhich, thanks to the low thermal conductivity of the material, guarantee good insulation.

Mixed frames are often used to improve the performance of windows and doors, thus exploiting the advantages of each material. For example in wood and aluminium frameswood has the structural and thermal insulation task while aluminium has the function of protection against external agents.

Determining the efficiency of window frames: thermal transmittance

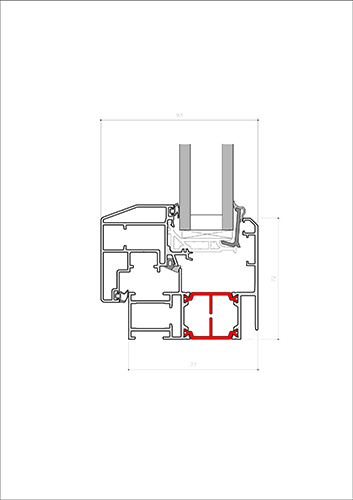

To assess the energy efficiency of a window, the reference parameter is the thermal transmittance U, whose value indicates the heat loss through the building envelope. For this reason, energy-efficient thermal break windows and doors are made to reduce thermal transmittance.

Thermal transmittance U is defined as the average heat flux that passes, per square metre of surface, through a structure that delimits two rooms at different temperatures. The unit of measurement of thermal transmittance is W/m2 K.

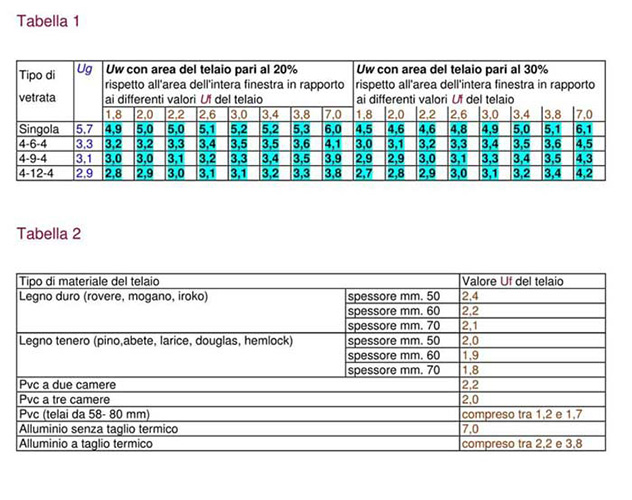

To know the thermal transmittance there are two methods: simplified calculation and rigorous calculation.

The simplified calculation

The simplified calculation is indicated by the UNI EN 10077 standard. It takes into account two tables, shown below. To calculate the thermal transmittance of the windows and doors (Uw) with the simplified calculation, you need to know the features thermals of frame (Uf), a value derived from table 2 and the thermal characteristics of the glass (Ug). Finally, once the percentage of frame on the entire window has been identified (20% or 30%) the value Uw of the frame by crossing the values of Uf e Ug reported in table 1.

Rigorous calculation

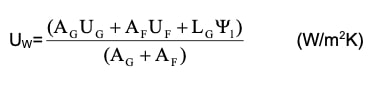

The other method to know the thermal transmittance of the window component Uw is the rigorous calculation which refers to the following formula:

Where:

UG thermal transmittance of the glazed element

UF thermal transmittance of the frame

Yl linear transmittance

LG perimeter of glazing

AG glazing area

AF frame area. Defined as the area of the projection of the frame surface on a plane parallel to the glass, it is the largest area between the area of the inner front surface and the area of the outer front surface.

The calculation of the thermal transmittance of the frames is a weighted average between the transmittance of the glazing Ug and the thermal transmittance of the frame Uf, plus the linear thermal transmittance Ψg, a value given by the interaction between the two components and by the presence of the spacer, applied along the visible perimeter of the glazing.

Systems and fixtures for thermal insulation of windows

The choice of window and door frames can be influenced by various factors: climate, budget or architectural requirements. Whatever type of window or doorframe you choose, it is always possible to benefit from tax deductions for the replacement of energy-efficient windows and doors, as long as the parameters set by the regulations are respected.

Among the aluminium thermal break windows and doors One of the best high-performance solutions is the Schuco AWS 75 SI system. A system with an open joint, Schuco AWS 75 SIThe ALUK 77 system for aluminium windows and doors offers exceptional thermal insulation performance of Uw up to 0.9 with triple glazing with Ug of 0.6. Similar levels of thermal transmittance (Uw up to 0.9 with triple glazing with Ug from 0.6) are also achieved with the ALUK 77 thermal break system for aluminium frames.

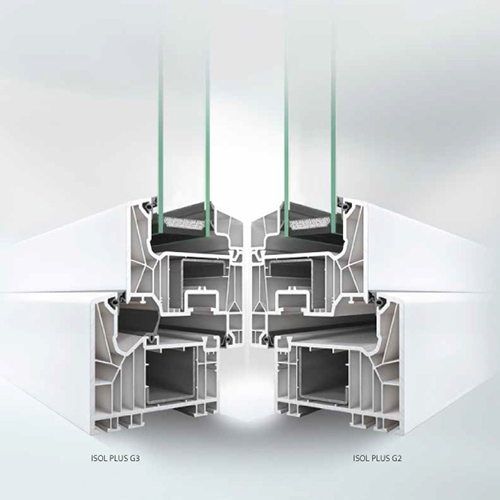

The SPI ISOL PLUS system for PVC windows, is one of the best solutions able to meet the most stringent criteria of thermal insulation. It guarantees a thermal transmittance of the window Uw up to 0.7. It can also be equipped with a double rebate seal system with or without a central fin seal.

For lovers of minimalist sections, SECCO's OS2 75 system is one of the best solutions for the steel thermal break windows and doorscapable of accommodating glass panes with a maximum thickness of 50 mm, guarantees thermal transmittance values of Uw = 1.04 with a thermal transmittance of the glazing Ug equal to 1.

Tax deductions: the requirements

The thermal transmittance parameters of the fixture are reference values to be known also in order to access the tax deductions provided by the Ecobonus 2020 for energy requalification.

The windows and doors must be chosen and configured respecting the minimum thermal transmittance values indicated in special tables, which vary from Region to Region and according to the climatic zones in which the property is located. For example, in Lombardy the limit value of thermal transmittance is from 2017 to Uw=1,4 W/m2K, a parameter that has been lowered, anticipating what will be expected from 2021 on the whole national territory.

If you are looking for quality windows discover our windows and doors.

Aluser, manufactures and installs quality building envelope solutions, contact us to schedule an appointment with one of our technical consultants.